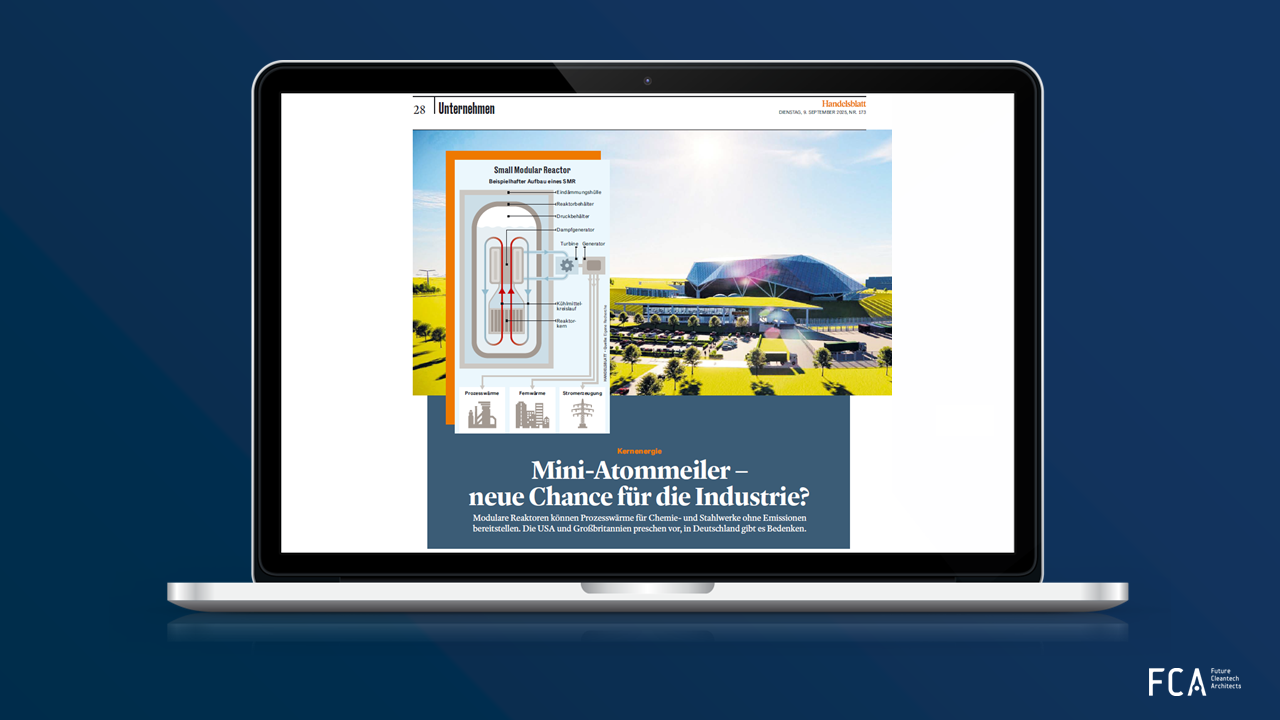

The chemical and steel industries rely on vast amounts of process heat, usually provided by fossil fuels. In the United States, companies are exploring a different path: building small modular reactors (SMRs) to supply its plants with clean heat. The project aims to cut half a million tons of CO₂ per year and could be completed by the end of the decade.

In Germany, such a development would currently be unimaginable. Yet across Europe and Asia, similar initiatives are emerging. SMRs could provide climate-friendly process heat at high temperatures.

“How can we design industrial processes so that they do not cause greenhouse gas emissions, but do not become more expensive?” asks our Cleantech Analyst, Peter Ruschhaupt. He sees both potential and risk in nuclear heat: “There are clear economic and technical reasons why nuclear heat can make sense. However, nuclear energy production has often turned out to be very expensive in practice. Whether small modular reactors will be different is hard to predict. High temperature electrified heat with storage will be a tough competitor.”

Learn more about the debate on small modular reactors and process heat in this month’s article from Handelsblatt (in German, paywall).

This article is the latest in the series “Green ideas that might change the world” that Handelsblatt and Future Cleantech Architects co-developed to shed light on some of the most intensively debated cleantech innovations. We are pleased to provide scientific guidance to the series. Stay tuned for new releases!