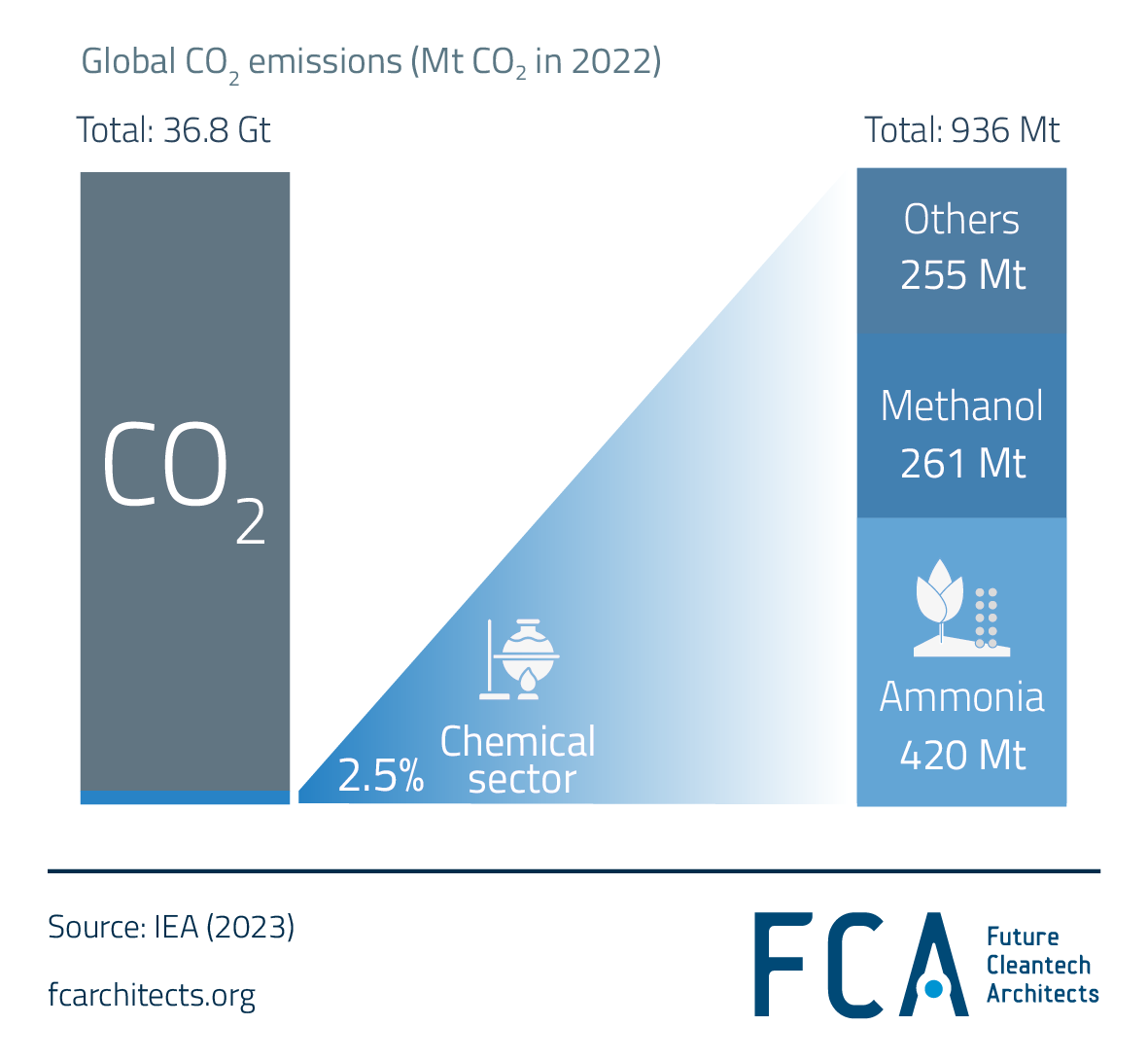

Ammonia is currently the largest emitter in the chemicals sector and contributes 1.3% to global annual energy-related CO2 emissions (i.e., emissions from energy combustion and industrial processes ~34.6 Gt in 2020). Manufacturing ammonia is also a highly carbon-intensive process, with hydrogen being a crucial feedstock in its production. Therefore, eliminating CO2 emissions from the production of ammonia is necessary step on the road to net zero by 2050.

Future Cleantech Architects is updating our work on Hydrogen, including expanding our assessment to the potentials and limitations of key hydrogen derivates, such as ammonia, e-methanol, and synthetic natural gas. Ammonia is the precursor to most fertilizers, which about 50% of the global population is dependent on to produce food. Currently, 70% of global ammonia demand is for fertilizers. The remaining 30% goes into a range of industrial applications: plastics, explosives, and more. In nearly all ammonia applications, ammonia is used as a precursor to the final products, with only 2% of the ammonia produced being used as the final product.

Green ammonia is chemically identical to conventional ammonia; however, the necessary hydrogen is produced via electrolysis of water powered by renewable electricity. As hydrogen is crucial for ammonia production, one of the priority areas for green hydrogen must be replacing currently used grey hydrogen.

While green ammonia leads to zero direct CO2 emissions, upstream indirect emissions remain. Moreover, it does not eliminate ammonia’s non-CO2 emissions. N2O is a greenhouse gas (GHG) with a warming impact ~300 times greater than that of CO2 and is released during the production of ammonia and the use of nitrogen-based fertilizers.

Finally, all green ammonia use must be prioritized to replace current ammonia produced and consumed before considering the use of green ammonia in novel applications.